FAQ's

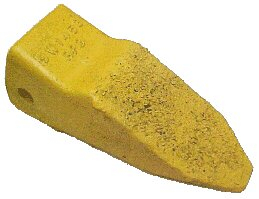

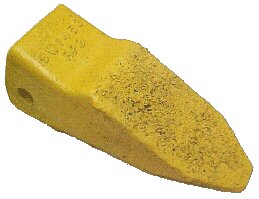

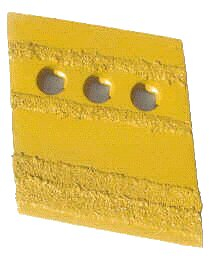

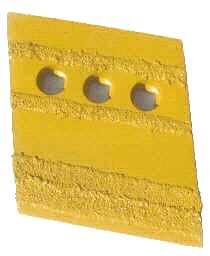

Does tungsten carbide work well on small size teeth?

The tungsten carbide impregnation process when applied to teeth has proven to be most successful with larger size teeth. The addition of tungsten carbide makes the tooth wear surface much harder, but at the same time more brittle and subject to breakage.