FAQ's

Can veiling profile be changed?

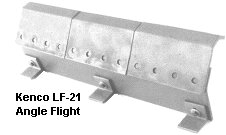

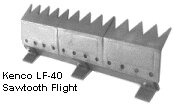

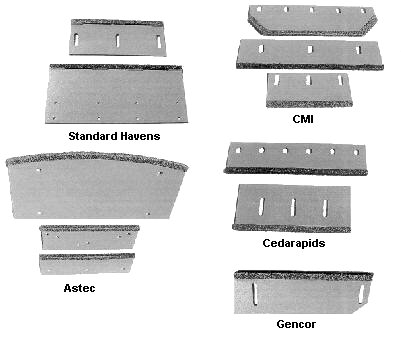

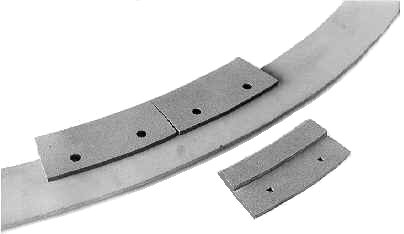

Kenco does not design or recommend flight styles/specifications, and is not responsible for material veiling profile inside the drum or dryer. Our flights match the dimensions of the worn original flights, but because of superior wear material, they will last many times longer.

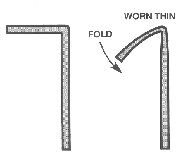

What are some of the problems associated with worn flights?

Worn flights inside a drum or dryer cause the veiling profile to deteriorate. When the veil is sub-optimal, aggregate material may not be properly dried, resulting in compromised mix quality. Improper aggregate drying will require the plant operator to slow down plant output and/or increase fuel consumption, both costly options. Kenco flights help avoid these problems because they significantly outlast all conventional flights.