FAQ's

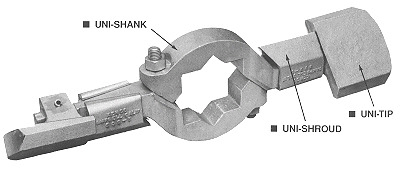

Must the entire pugmill be converted to Uni-Mix at the same time?

No. Paired Uni-Mix sets can be installed anywhere in the pugmill, right alongside OEM parts.

Why is there more than one notch on Uni-Shanks?

Several notches are cast in Uni-Shanks to accommodate special liner thickness, modifications to OEM plant dimensions, or individual preference of tip-to-liner clearance. After installing Uni-Mix parts, always ensure proper clearance exists between Uni-Tips and liners before mixing production begins.