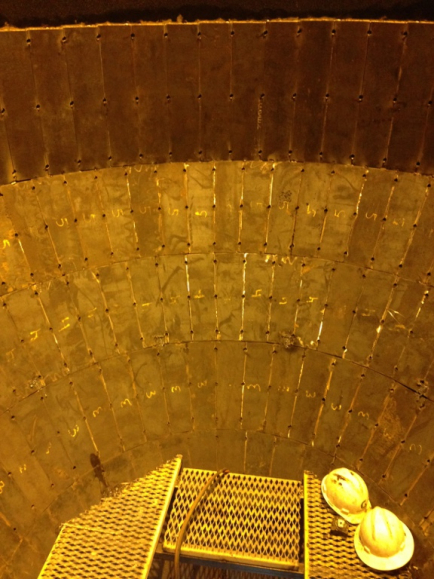

Storage Silo Cone Liners

Kenco Silo Cone Liner Kits consist of 20-25 lb. factory-cut trapezoid pieces, sized by our computer model to be quickly and safely installed without the use of a crane. Smaller, lighter pieces, along with secure weld-on installation, offer several important advantages to Kenco Liners over other cone liner replacement options.