FAQ's

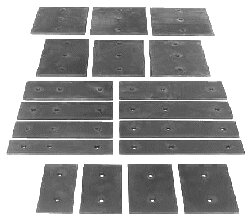

Can Kenco Wear Plates be cut?Yes. A plasma cutter is recommended for cutting Wear Plates, but an abrasive cutoff saw will also work. WARNING: excessive heat generated by an abrasive cutoff saw may cause Wear Plates to crack or break. Kenco can plasma cut all Wear Plates in our factory.

Can Kenco Wear Plates be welded?No, the alloys in Kenco Wear Plates are not suitable for welding. For

weld-on installation use Kenco cone-shaped weld washers. Simply insert the proper size weld washer in the casting holes and arc weld to the sub-floor.